We specially design and present the reports you need according to the sector you work in the belt scale. Belt scale system can be installed in the primary breaker and bypass separation sections according to the production line in quarries. Accordingly, stone/bypass analysis helps you measure the efficiency of the quarry, instantly see the amount of your production stocks, and analyze the factors that will affect other production in the quarry.

However, since just plugging the belt scale into the system will not meet your needs, a computer and software connected to this computer are needed that will collect all the data and enable them to be analyzed. These softwares are prepared by our company by customizing according to your sector and needs. In addition, a few sample applications are available in the images.

We specially design and present the reports you need according to the sector you work in the belt scale. Belt scale system can be installed in the primary breaker and bypass separation sections according to the production line in quarries. Accordingly, stone/bypass analysis helps you measure the efficiency of the quarry, instantly see the amount of your production stocks, and analyze the factors that will affect other production in the quarry. However, since just plugging the belt scale into the system will not meet your needs, a computer and software connected to this computer are needed that will collect all the data and enable them to be analyzed. These softwares are prepared by our company by customizing according to your sector and needs. In addition, a few sample applications are available in the images.

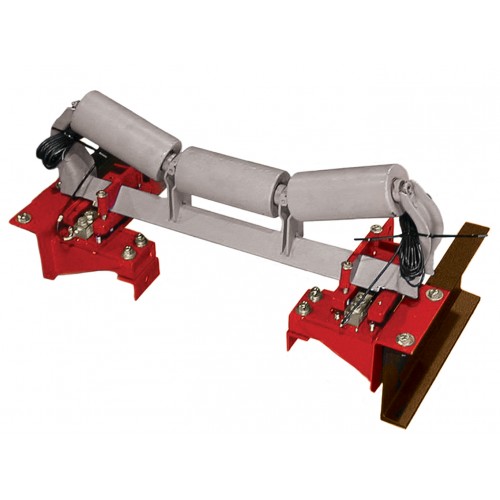

It is used to measure stock and capacity information of the facility by weighing stone, copper, coal and other mines on the belt. It is recommended to perform a calibration check once a week in order to make belt scale weighings stable and accurate. There is a 3% margin of error in international standards. (Based on our field experience, we can safely say that this rate does not exceed 1% if the necessary maintenance is done and the right equipment is used.) Our belt scale software supports TCP/IP Modbus protocol. It can receive data from all band scale indicators working in this protocol.

It can receive and store data from more than one belt scale at the same time. It provides you detailed information about the ratio of the products weighed with the adjustments made in it. If My Facilities Cloud system is used, you can transfer the produced product to the stock warehouse and check the stock according to the usage or sales rates, and you can get all your reports from your mobile phone, tablet, desktop and bag computers. The system is in SQL database structure.