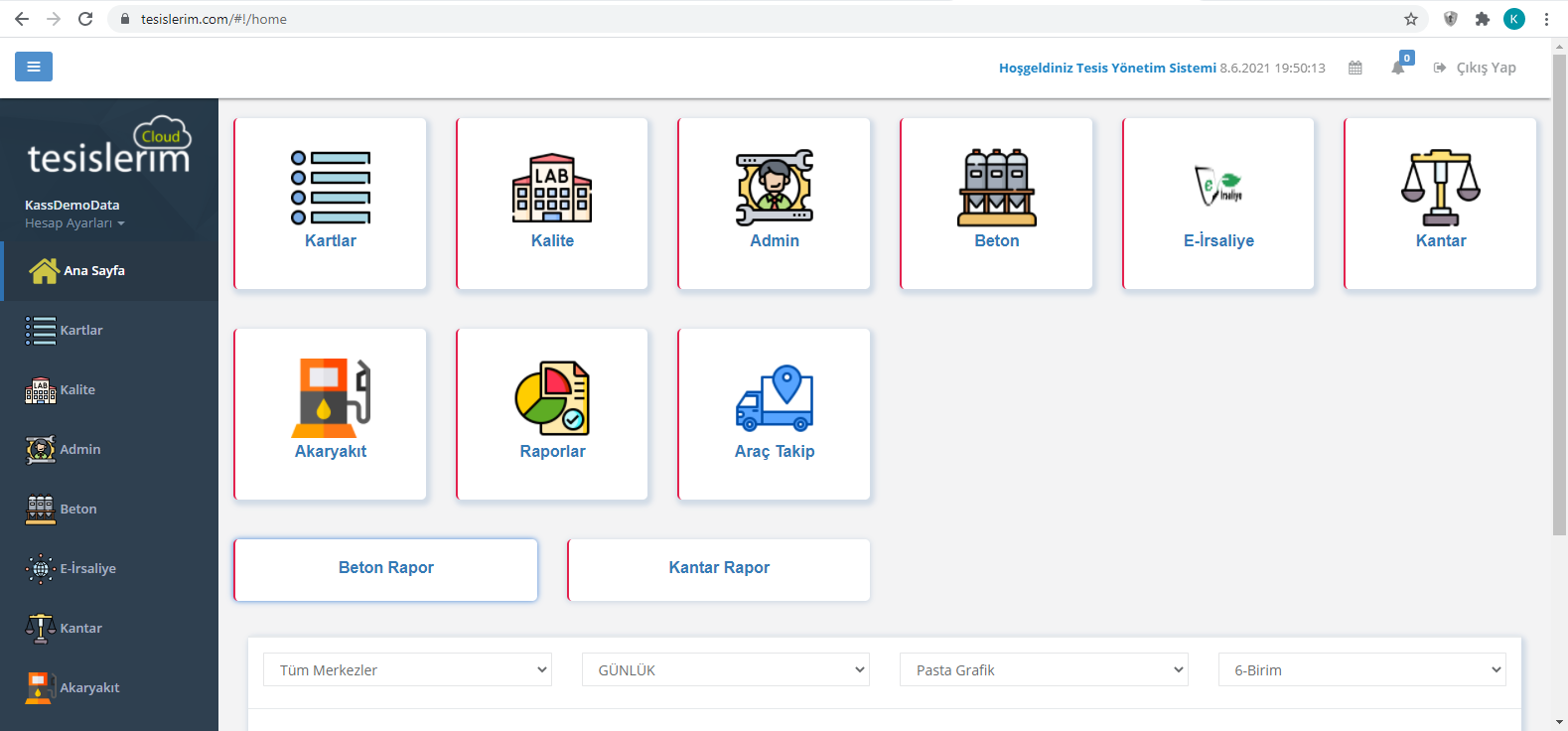

Our system can work integrated with all SQL database (Firebird, PostgreSQL, MSSQL, MySQL) automation systems. With an application to be installed on your power plant automation system, you can use it on the web (www.tesisresim.com), your panel opened specifically for you, or your mobile (https://play.google.com/store/apps/details?id=com.kassyazilim.tesisresim&hl=tr&gl= US) you can manage your concrete plants (concrete production facilities).

Central concrete system software can be used not only in concrete plants, but also in construction sites, fuel automation, weighbridge automation and anyone who needs a quality management system.

Since 2017, we have been constantly renewing our cloud-based structure with daily updates. All the newly added features are available to all our customers at the same time.

1. You can get the construction site location information from the vehicle location, address, route of the vehicle and mark it. It calculates the distance of your concrete batching plants from the customer construction site from the map module.

2. It can manage your concrete shipments. You can open a panel for your customers and your customers can monitor their own shipments on their mobile phones. It can view the information of its own shipments, the approximate arrival time according to the vehicle location, arrival mileage and traffic situation with the integration of the vehicle tracking system.

3. You can monitor the recipe usage information of the concrete you ship in your concrete shipments. If you use Kass Ready-Mixed Concrete Production Automation, you can update the recipe information at all your facilities at the same time.

4. You can report your e-Waybills of your shipment and transfer your waybills to the accounting program.

5. You can see your instant power plant stock information and place your cement, mineral additive or chemical additive orders before the stock runs out.

6. You can create your ready-mixed concrete orders for production and accordingly the status of your shipments, namely how many orders you have, the fulfillment rates of the orders and the forward-dated shipment planning, and transfer your orders to your plant production automation. In addition, this system will provide you convenience in your concrete planning according to your daily production capacity.

7. You can generate and analyze your fuel reports, fuel tank status liter/m3 & liter/km and performance reports of your vehicles.

8. You can monitor your purchase and sale of goods on your scale and check the stock status according to the status of purchases or sales (entries or exits). At the same time, you can continuously control the production calibrations of the plant by weighing your produced concrete and comparing the plant production kg with the weighbridge kg information.

9. You can report your concrete strength, methylene blue, Log Angeles and other laboratory results by logging in here.

10. There are tools to help you design a recipe according to the standards and the results of your experiments.

11. There are tools that allow you to transfer your recipes to your automation.

12. If the integration with the vehicle tracking system is established, the system can calculate the concrete pouring area of the truck mixers and the construction site road route online and access information such as the instant location of the vehicle, the remaining km, and the arrival time, including the traffic situation. You can automate this information from the features section of the system and send it to customers via automatic sms or mail.

13. With accounting integration; Current, stock, warehouse, personnel, vehicle information in your system is instantly transmitted to the cloud infrastructure, and the movements that occur accordingly are automatically ready to be transferred to the accounting system.

14. You can get Current Extre / Current Balance information with My Facilities Cloud infrastructure. Sales and Finance salespeople can instantly access the current balance and statements they want, without keeping the accounting busy.

15. You can check the actual recipe usage and weighing results of the productions on the system.

16. If you have a quarry, you can monitor instant production information from the system with our belt scale software and see how many tons/hour you have produced, in performance and stock reports.

We update our system with daily / weekly plans and make them available to our customers. We respond quickly to the needs of our customers.

In short, we meet all the requirements to control your concrete batching plants and construction sites. In line with your needs, our software department evaluates your requests that you will create from the support department, and if you have a request that will cover all users, we add these features to the system free of charge and make them available to all our customers.

Since our system uses the cloud infrastructure, your data allows you to monitor your reports on www.tesisresim.com without the need for any infrastructural hardware (server, etc.). In short, if you want to monitor / manage your system, you only need to connect Kass Ready Mixed Concrete Management and internet to your facility.